Matte finishes are among the most requested options in wood flooring, prized by homeowners and commercial clients for their modern, natural aesthetic. They reduce glare, subtly enhance the wood’s character, and hide dust better than glossy coatings.

But achieving this understated look isn’t simple. Unlike glossy finishes, which reflect light uniformly and can mask minor imperfections, matte coatings scatter light in multiple directions. This makes sanding marks, film-thickness variations,

and application flaws far more visible, placing higher demands on surface preparation, technique, and product performance.

The Science Behind Matte

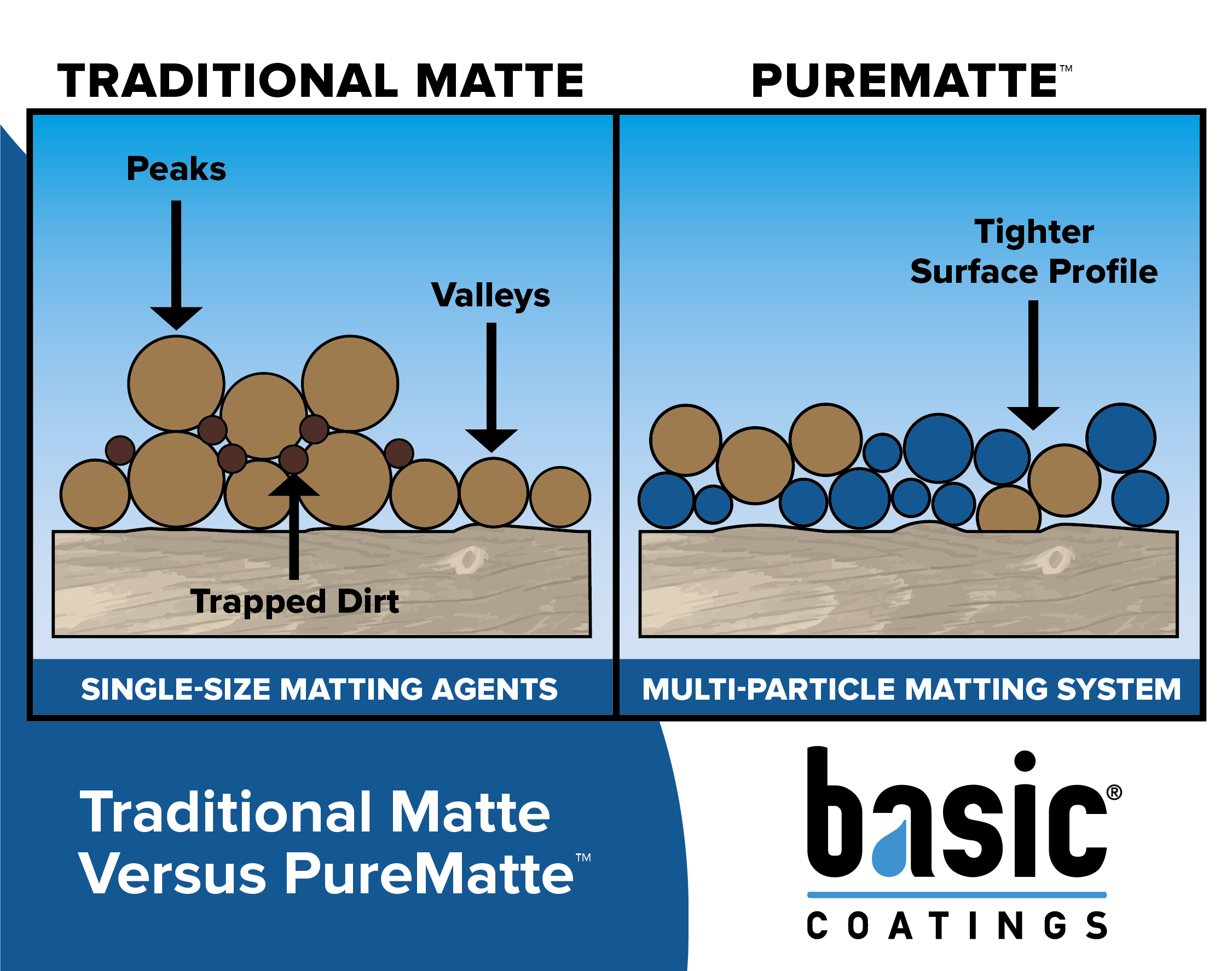

Matte finishes use tiny particles called matting agents to scatter light and reduce gloss. Traditional formulas often rely on single-size particles, which create microscopic peaks and valleys in the coating film. While this achieves a matte look,

it also introduces challenges:

- Uneven appearance: A hazy or inconsistent look under angled lighting.

- Dirt buildup: Textured surfaces can trap dirt, making cleaning more difficult.

- Marring: Softer, textured films are more prone to scuffs and scratches.

In other words, the same properties that make matte finishes appealing also make them more difficult to apply evenly, maintain, and protect over time.

Stay Informed: Bring Out the Best in Every Floor with Basic Coatings

Subscribe to Basic Coatings emails to join thousands of industry professionals and receive the latest product news, expert tips, training resources, and event invites—delivered straight to your inbox!

Yes, Sign Me Up!

The PureMatte™ Difference

PureMatte™, the ultra-matte counterpart to StreetShoe® NXT,

is designed to overcome these challenges. This two-component water-based finish delivers a gloss level of 5 or less — providing that desirable flat, “bare wood” look — without sacrificing performance or application

ease.

Advanced Particle-Size Technology

Instead of relying on a single particle size, PureMatte uses a multi-particle matting system — a precisely balanced blend of different particle sizes that creates a denser, more compact, and more consistent film:

- Larger particles scatter light to achieve low gloss.

- Smaller particles fill the gaps between them, reducing peaks and valleys.

This combination forms a tighter surface profile compared to traditional matte finishes, as shown in the diagram. While single-size matting agents leave large gaps (valleys) where dirt can collect, PureMatte’s multi-particle system fills

those spaces to create a denser, more uniform finish.

The result is a cleaner, more refined surface with fewer imperfections, improved resistance to dirt and debris buildup, and a consistently beautiful finish. This tighter surface profile means easier upkeep for clients and less frequent maintenance

for contractors.

Engineered for Durability

PureMatte isn’t just about looks. It features a curated urethane resin system designed to perform in high-traffic environments, delivering:

- Abrasion resistance to withstand heavy use and routine cleaning.

- Scuff and mar resistance to protect against everyday wear.

- Chemical resistance to guard against spills, household cleaners, and common stains.

Extensive testing ensures PureMatte maintains its ultra-matte appearance even in kitchens, entryways, and commercial spaces — areas where flooring takes the hardest hits.

Support Beyond Application

For contractors, PureMatte simplifies the process of achieving an in-demand look . For clients, maintaining it requires a thoughtful approach. Simple care habits — such as avoiding harsh cleaners and polishing products that alter sheen

— help preserve the matte appearance over time. Opting for Squeaky™,

a gentle yet effective cleaner that's tough on dirt but preserves finish integrity, ensures ongoing care without compromising the appearance of the floor.

Upgrade to PureMatte

PureMatte delivers what others can’t: the ultra-matte, “bare wood” look clients want, combined with the durability, cleanability, and ease of use professionals demand. Experience the difference advanced particle-size technology

and robust urethane chemistry can make in your next project. Click here to learn more.